Duties of Seamen in Ship's Engine Department

Engineering Branch Training. United States Maritime Service Training Manual. War Shipping Administration Training Organization, published for United States Maritime Service by Cornell Maritime Press, 1943, 1944

The first sight of a ship's power plant in operation is apt to be a fascinating spectacle of large whirling cranks; gleaming piston rods, sliding in and out of huge lofty cylinders, and of roaring fires in the furnaces. The maze of pipe lines and smaller machinery gives the impression of a complicated assembly requiring much time to understand. Nothing could be further from the truth, for the principles of operation are simple if followed step by step.

Model of Liberty Ship Engine at right

To propel the ship through the water a propeller is used at the stern. It must have an engine, either steam or internal combustion to turn it. Various smaller machines are necessary for the operation of the main engine. If a steam engine is used, boilers will be required to furnish the steam for the engine. Fuel and a place to store a sufficient amount for a long journey is also required. Tools and spare parts for the various machinery must be aboard. Sufficient fresh water for the crew and plant's needs and a place to store it is necessary. It must be remembered that a ship is a virtual floating city which must be able to maintain itself and effect necessary repairs independent of any outside help for considerable periods of time.

The safety of the ship is dependent to a considerable degree on you Firemen, Watertenders and Oilers, for one of the most important needs of a ship's power plant is a well trained and competent engine room crew. The best machinery is no better than the men who operate it and care for it.

The members of the Engine Department with brief mention of their duties are listed according to their rank and authority.

Licensed Officers

Chief Engineer -- In charge of and responsible for all of the machinery aboard ship.

First Assistant Engineer -- In charge of maintaining machinery in fireroom and engine room. Stands 4-8 watch.

Second Assistant Engineer -- Responsible for fuel oil, fresh water and care of the boilers. Stands 12-4 watch.

Third Assistant Engineer -- Maintains electrical equipment and auxiliaries under direction of the first assistant. Stands 8-12 watch.

Junior Engineer -- (May or may not be licensed.) Stands engine room or fireroom watch under regular watch engineer on larger ships.

Unlicensed Qualified Members of the Crew

Deck Engineer -- Keeps in repair all deck machinery, such as cargo winches, anchor windlass, etc. Works day work.

Oiler- -- Oils the bearings of the main engine and auxiliaries. Stands watch in engine room.

Watertender -- Maintains proper water level in boilers and has charge of firemen. Stands watch in fireroom.Fireman -- Operates oil burning system to generate steam in boilers and on small and medium sized vessels also acts as watertender. Stands watch in fireroom.

Unlicensed and Unqualified Member of the Crew

Wiper -- Performs manual labor in engine department, such as cleaning and painting and assists in repair work. Works day work.

Unlicensed Members Carried on Some Vessels in Addition to Above

Machinist -- Performs necessary machine repair work. Works day work.

Refrigerating Engineer -- Operates and maintains refrigeration systems on refrigerator vessels.

Electrician -- Carried on vessels which have considerable electrical equipment.

Pumpman -- Always carried on tanker vessels. Operates and maintains cargo pumps and valves.

Storekeeper -- Keeps check on supplies and spare parts on large vessels.

The importance of the duties of each member of the crew cannot be overemphasized.

Should the fireman through neglect or ignorance allow the water level in the boilers to drop below the lowest safe point, serious damage may occur with resultant loss of use of the boilers and stoppage of the ship's engine.

Likewise, should the oiler burn up a bearing on the engine, the engine may have to be stopped for repairs.

These events are serious in that the stopped vessel would have to drop out of convoy making it easy prey for attack. A smoking stack may give away your position to the enemy and bring on attack.It is therefore evident that these duties must be carried out by men who know their business. No one in training can afford to waste a single moment of the time, for your life may depend on what you know. Close attention should be paid to all lectures and practical work. The manual should be thoroughly read and understood and kept with you for reference when you go aboard ship.

The prompt execution of orders is an absolute necessity for safety of the vessel and crew. Delay in the closing or opening of a valve for example can result in serious damage.

Duties of an Oiler

Remember -- A Wiped Bearing May Stop your ShipAt sea the main engine usually turns at a steady speed although in convoys the speed will quite often be varied from time to time. The oiler makes regular rounds usually every half hour feeling all of the various bearings on the main engine and oiling them. He also must swab the piston rods and valve stems. He also feels of the thrust bearing and travels down the shaft alley feeling and oiling the spring bearings and feeling the stern gland and looking to see if sea water is running through.

|

|

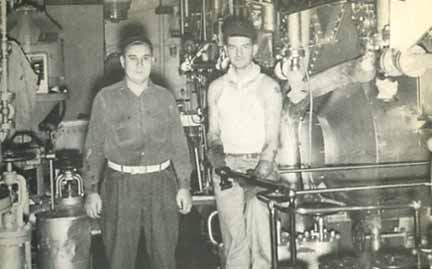

| Trainee oiling Liberty ship engine | Engine room trainee checking temperature |

In between his regular rounds the oiler checks the engine room auxiliaries, refrigerating system and steering engine. He should know how to stop the main engine should it become necessary and the engineer were absent.

It is the oiler's duty to learn everything possible in connection with the operation of the vessel's power plant, because when opportunity comes for advancement he will be able to qualify for the position of watch engineer.

All oilers should thoroughly understand the operation of the different types of lubricating oil pressure and gravity systems for turbine lubrication.

The actual oiling of the machinery takes up but little of the oiler's time. However, he should have the plant under his constant surveillance.

The oiler's watch at sea is of four hours, with eight hours off in between. In port on some vessels, his duties consist of day work, while on other vessels his watch is eight hours long, with sixteen hours off in between.

During his watch, the oiler is probably called upon to do one or all of the following. Pump out the bilges, pump up fresh water or ballast tanks, keep an eye on the water level in the boilers and on the fireman, take temperatures of the stack, sea water, filter box, and feedwater for entrance into the logbook, keep oil wiped up off the floor plates and gratings, and on some ships he has a station to keep clean.

In port his work consists mainly of oiling the auxiliaries, and in assisting in the maintenance and repair of the plant. He may be called upon to oil and watch the cargo winches during the night if the cargo is being worked at that time.

His is a responsible job; his negligence may result in damage to machinery to the extent of thousands of dollars.

Duties of a Fireman

The fireroom watches are of four hours each. This means that in 24 hours there are six watches; the 12-4, 4-8, and 8-12 A.M. and P.M. A fireman stands an A.M. and a P.M. watch, with eight hours off in between.

The oiler on watch rings "two bells" on the engine room bell at ten minutes before the relieving hour. The relieving fireman enters the fireroom at this time and begins his inspection of the plant.

The first and most important thing that the fireman looks at on entering the fireroom is the boiler gage glasses. Make certain that the water in the boiler is at its proper level. If the fireman is responsible for tending the water in the boiler, blow the glasses down to ascertain the accuracy of the water level. The fireman works under the direction of the watertender if one is on watch.

The fireman then makes an inspection of the fires an the burners. Take note of the condition of the tile cone around the burner front to see if there is any carbon built up in front of the atomizer upon which the oil will impinge. Look for oil leaks at the connections of the oil lines and burners. Inspect the fireroom and the tank tops below the floor plates for oil drippings that may cause fires. Make sure that all spots of oil are wiped up on the floorplates and in the pans below the burners. Take note of the pressure gage readings at various points in the oil line to ascertain the conditions of the oil strainers. Check the oil heaters by looking at the thermometer on the oil line to see if the proper temperature is being maintained. Look in the fireroom bilges to see that they are empty, check the pressure of the oil in line at the gage nearest to the burners, and then the steam pressure of the boilers. After everything is apparently all right ask the fireman who is going off watch if he has had any trouble during his watch, and if there are any special orders for you from the engineer. If all is found to be as it should be, take over the watch, relieving the fireman on duty of all responsibility.

The fireman should never be lax or late in his inspection when relieving a watch. Always remember that when you relieve the other man, the full responsibility for the maintenance of the fireroom is yours for the next four hours. Whatever conditions may exist, regardless of who is to blame, the responsibility will be yours alone.

Always allow yourself enough time to make your complete inspection before eight bells ring in the engine room. This marks the beginning and ending of the watches. Never make a man you are relieving remain below after his watch is over unless you find something wrong due to his negligence while he has been on watch. In this case do not relieve him until he has remedied the condition.

After taking over the watch, the next problem is to make sure that everything goes smoothly during your watch. Change over the suction and discharge strainers and clean the ones that have been in use, replacing them in the body of the strainer, and leave the strainer and floor plates around the strainers clean for the next watch.

Next change all burners. These are changed alternately from boiler to boiler and never more than one in a boiler at a time. While a burner is being changed it is out of use for the few minutes that it takes to complete the operation. During these few minutes, there is the same amount of water entering the boiler as before but there is less steam being made. Therefore an excess amount of water accumulates, raising the level in the boiler.

After the burners have been changed and cleaned, the strainers changed and cleaned, and the watch is running smoothly, the fireman's duty is to make an inspection of the plant at definite intervals. Don't just sit down and wait for your relief. Trouble is a thing that will come quickly to the lazy fireman. A small speck of dirt the size of a pin point can stop up a burner to the extent that the direction of the oil spray can be diverted enough to strike the brickwork of the furnace. This oil does not burn but cokes and forms carbon on the brickwork. This carbon continues to build up and in the short period of a half-hour a piece of carbon large enough to completely block the burner opening can form. This will cause improper combustion in the furnace and soot will form on the tubes of the boiler causing considerable loss of efficiency and a lot of work.

|

|

| Lighting off an oil burner | Trainees at the engine room telegraph |

The fireman must watch his plant at all times just as the engineer watches his.

Each fireman is responsible for keeping a part of the fireroom in a neat and tidy condition. The particular part being known as your station. The painting, shining of bright-work, etc., connected with this station is done by the fireman while he is on watch. However, this work is never in such a part of the fireroom that at any time the performance of these duties interfere with the safe operation of the boilers. At all times, the fireman should be at a point where his water gage and steam pressure gage are visible.

A fireman should do everything possible to maintain the boilers in a safe operating condition at all times with a maximum of efficiency. You should be familiar with the pipe lines and auxiliary machinery in the fireroom and know how to prevent and combat fires that may start at any time.

Keep a close watch on the stack for smoke, either by looking at the top of the stack itself or through the smoke density indicator.

Duties of a Watertender

The watertender is carried aboard ships which have several boilers and where the tending of the water in the boilers requires constant attendance. Some boilers, such as the Scotch boiler, although they require constant attention do not require that a change in the setting of the check valves be made often. Other boilers require frequent change in the setting of the check valves in order to maintain the proper water level in the boilers.

The duties of the watertender include the following: Be thoroughly familiar with the construction of the boilers, the accessories connected with them, and know their purpose and operation., These accessories include the external and internal feedwater lines, and the stop and check valves that control the feeding of the water to the boiler, the safety valves, the main and auxiliary steam stop valves, the steam pressure gage, the water column and gage glasses, the injector, the feed pumps, try cocks, bottom and surface blowdown valves and piping connected with blowing down the boiler, the hand release on the safety valve, superheater drains and connections, air cock, all valves used in conveying steam from the boiler to all parts of the ship, smoothbores, etc. The watertender must at all times be aware of the hazards incurred from low water and maintain a safe level in the boilers.

Because the firing of the boiler directly affects the water level in the boiler, the watertender must direct the fireman in his duties. He oversees the fireman and as a rule, is responsible for maintaining a steady steam pressure in the boiler.

When the boilers are supplied with automatic feedwater regulators, the watertender should be familiar with their operation, and should never rely entirely on their operation, but still maintain a constant surveillance of the water level.

The watertender must have a thorough knowledge of the engine and fireroom firefighting equipment.

The watertender should be thoroughly familiar with the safe handling and burning of fuel oil. He must be able to properly operate the fuel oil system from the tanks to the burners. This requires a thorough knowledge of all the oil burning equipment including the transfer lines and pumps, valves, manifolds, etc., strainers, service pumps, heaters, control valves, atomizers, and regulating valves.He should have a good working knowledge of draft, and the particular draft equipment on the vessel on which he is employed, for it is his duty to minimize smoke conditions at the stack, and maintain good furnace conditions.

In short, the watertender should be able to operate and maintain the fireroom watch with as little assistance from the engineer as possible.

|

| The Fireman and Watertender must adjust numerous valves and watch many gauges, for boilers allowed to run dry will explode |

The Wiper's Job

The wiper is not a qualified member of the engine room in the true sense of the position. He is an all-around worker in the Engine Department of an oil-fired vessel. His is the only position open in that department for beginners and others not qualified in the more responsible ratings. The wiper washes paintwork, chips, scrapes, paints, and performs all those various duties tending to maintain the machinery spaces in a clean condition.

Where overhauling and repair work of boilers and machinery is carried on, the wiper helps in various ways, and it is through the knowledge that he gains while doing this work that he prepares himself for advancement.

Since he is first, last, and always a seaman, he should be familiar with nautical terms. He should realize the importance of emergency drills, know his stations in each, and be able to fulfill his part should the necessity arise to combat fire or abandon ship. As an engine department worker he should have an interest in mechanics, and be familiar with the names and the purposes of all the units in the power plant of the vessel.

Generally he is a day worker, and is not assigned to a watch. He should, as quickly as possible, familiarize himself with the hazards of using oil fuels, and operating pressure vessels.

Sources

United States Maritime Service Training Manual. War Shipping Administration Training Organization, published for United States Maritime Service by Cornell Maritime Press, 1943, 1944

Lent, Henry B. Ahoy, Shipmate! Steve Ellis Joins the Merchant Marine. New York: The Macmillan Company, 1945

Douglas, John Scott and Salz, Albert. He's In the Merchant Marine Now. New York: Robert M. McBride and Co., 1943

Official Training Aids Photos. U.S. Maritime Service, Sheepshead Bay, NY. [Courtesy Jane Cady]Duties of Seamen in Deck Department

Duties of Seamen in Stewards Department

07/27/06

www.USMM.org ©1998 - 2006. You may quote material on this web page as long as you cite American Merchant Marine at War, www.usmm.org as the source. You may not use more than a few lines without permission. If you see substantial portions of this page on the Internet or in published material please notify usmm.org @ comcast.net